Description

Do your bags melt during the packing process and the machine fails to extract all of the air? The problem is not the machine! Check what bags you’re using. The composition and thickness of the Status vacuum sealer bags guarantee that the foods will be vacuum-packed to a high standard.

Factors determining vacuum bag quality

Vacuum bags have to be of the appropriate thickness and composition because these two factors significantly impact the vacuum packing process and quality. Status vacuum bags are the thickest on the market. The smooth part is 100 µm thick, and the ribbed part 120 µm. This means that the bags will not tear when you store them in the freezer, the meat will not get rancid, and the nutritional value of your fruits and vegetables will be preserved better.

What are our vacuum sealer bags made from?

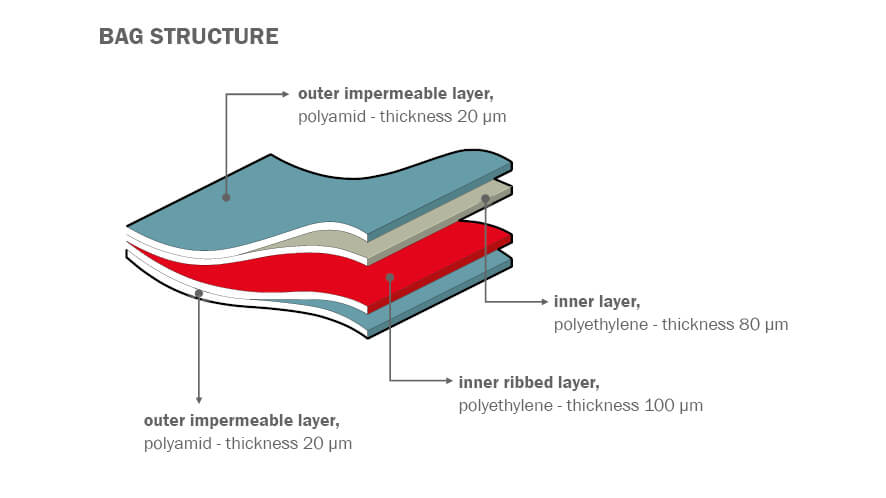

Our vacuum bags are made from a combination of polyamide (PA) and polyethylene (PE); these materials are important because they determine the degree of the bags’ impermeability and guarantee a good seal or fusing.

Status bags have a 20 µm thick outer polyamide layer, which ensures their impermeability. This is the thickest layer of PA available on the market. The food items will stay completely shielded from external factors such as air and other aromas. The other material, which ensures the bags will fuse well, is polyethylene. It is used in the inner layers and is food safe, which means that the vacuum-stored foods will not adopt the unpleasant smell of plastic.

The ribbed foil’s pattern is also important

The distinct shape of the ducts in the ribbed layer ensures that the air will be extracted from the bag effectively without little air pockets forming around the food items. The vacuum-packing foil must be ribbed at least on one side because two smooth sides would stick together during the vacuuming process, which would make the process of extracting air from the bag practically impossible. The Status bags’ ribbed profile is 0.2 mm thick and is an important factor in guaranteeing the quality of vacuum packing in a series of consecutive cycles.

Video: How the quality of bags affects the process of vacuum packing?

Top-quality materials with certificates

Status vacuum bags are made in Slovenia using materials of European origin. Their high-quality materials guarantee that the bags are:

- impermeable,

- food safe,

- neutral in taste and smell,

- suitable for reuse,

- suitable for sous vide cooking.

Why vacuum pack?

By extracting air using a vacuum packing machine, you create vacuum in the bags. This removes oxygen, which is food for bacteria, and so stops food from degrading. Your foodstuffs will last up to four times longer and stay fresher. What this means for you is that you’ll throw away less food and that the foods in your freezer will be stored to a high standard without taking on smells of other stored foods or the freezer itself. Even after a long time in the freezer, food items sealed in high-quality vacuum bags will taste the same as they did on the day they were packed. Bake bread or a fruitcake then vacuum pack and freeze it. You’ll be able to serve your tasty homemade snack to any unexpected guests in no time.

Vacuum bags sized 280 x 360 mm (71.1” x 91.4”) are suitable for vacuum packing:

- bigger cuts of fresh meat and dried meat products,

- bread or fruitcake

- vegetables and fruits for the winter,

- walnuts and hazelnuts.

Status Stiki

You can make the process of vacuum packing in vacuum bags using Status vacuum packing machines easier by using Status Stiki double-sided adhesive tape, which attaches to the bag as soon as it touches it so there is no need to hold it. It enables you to save on bags and foil and helps keep the bag straight and wrinkle-free during the vacuuming process.

Customer Rating

There are no reviews yet.